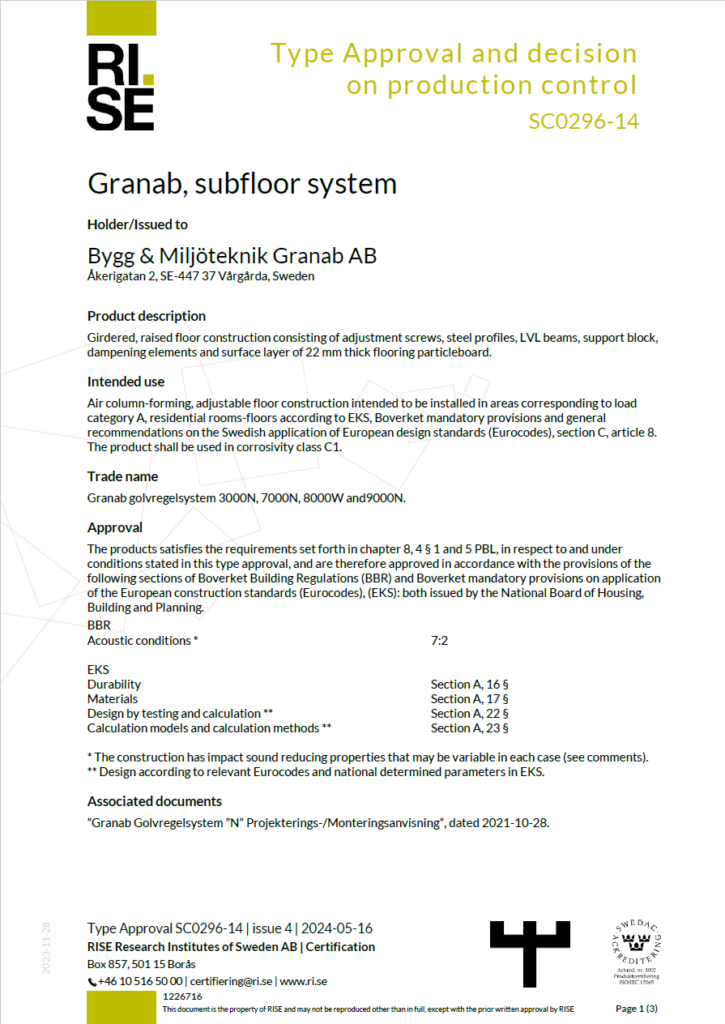

Certificate

Type approval of Granab subfloor system at SP Technical Research Institute of Sweden.

Granab subfloor systems 3000N, 7000N, 8000W and 9000N are tested and certified by SP Technical Research Institute of Sweden for load-bearing capacity, stability and ageing resistance with verified values for sound-absorbing properties.

Granab subfloor system fulfils the requirements of Chapter 8, 4 § 1 and 5 PBL in the respects and under the conditions specified in the type approval and is therefore approved by the Swedish National Board of Housing, Building and Planning (BBR) and the Swedish National Board of Housing, Building and Planning’s regulations and general advice on the application of European construction standards (EN).

- Certificate and type approval SCO296-14

- Certificate and type approval 19 21 01

Basis of assessment

Reports 4P02040, 3P04159-A, 3P04159-C, 3P04159-E, 4P02605-B, P302700C, 3P03903, P501330-1, P705473, PX05294A, PX05294B, 4P00999, 3P05281 and statement P503562 from SP Technical Research Institute of Sweden.

Download our EPD’s or contact us for the full LCA on all systems.

Testing and certification of Granab subfloor system at SP Technical Research Institute of Sweden.

01

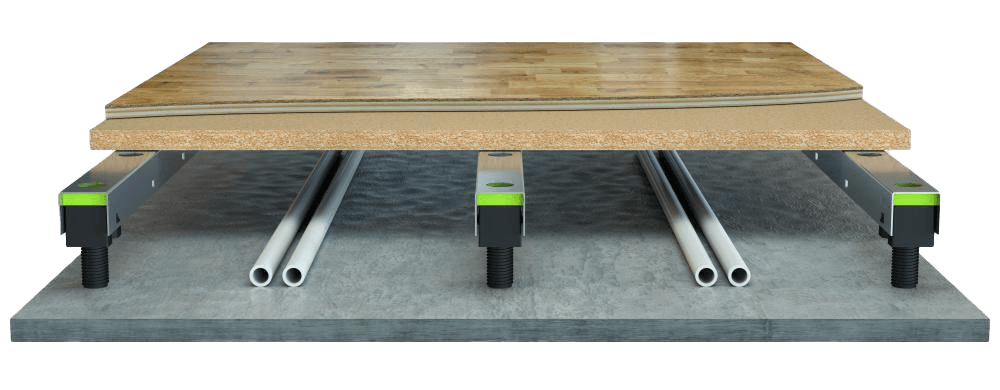

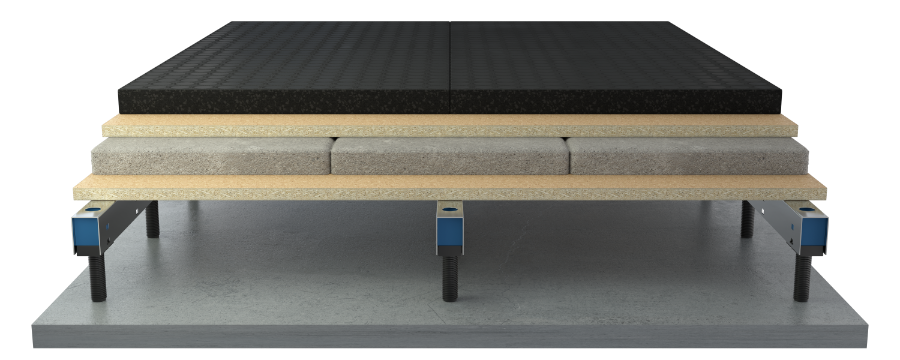

Deflection

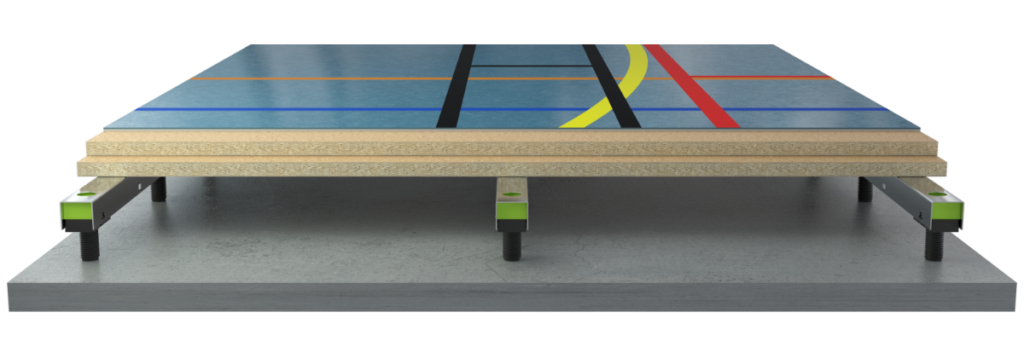

Deflection at point loads in floors laid on the Granab system is, in addition to the structure of the subfloor system and the c/c distance between the girders, dependent on the choice of floor surface layer and installation design. The respective manufacturer of the floor surface layer provides information on deflection for each floor surface layer.

02

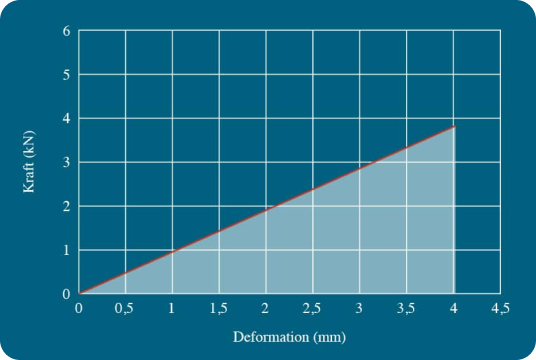

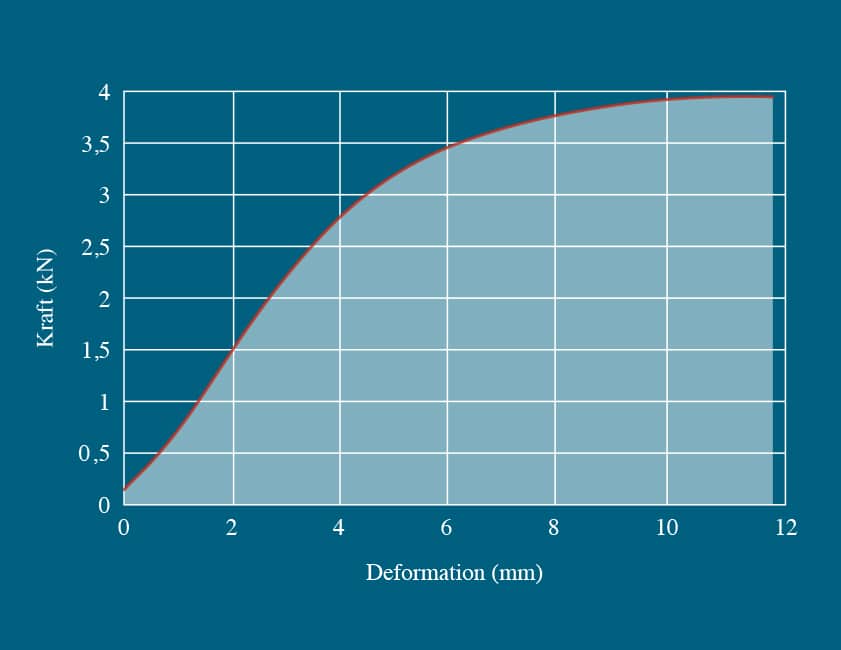

Load test 1 separate support block/adjustment screw

Support block loading performed by placing a support block with a adjustment screw between two steel plates and loading it using a hydraulic press. Force and deformation were recorded. When tested, only 10 mm of the adjustment screw was threaded into the support block.

03

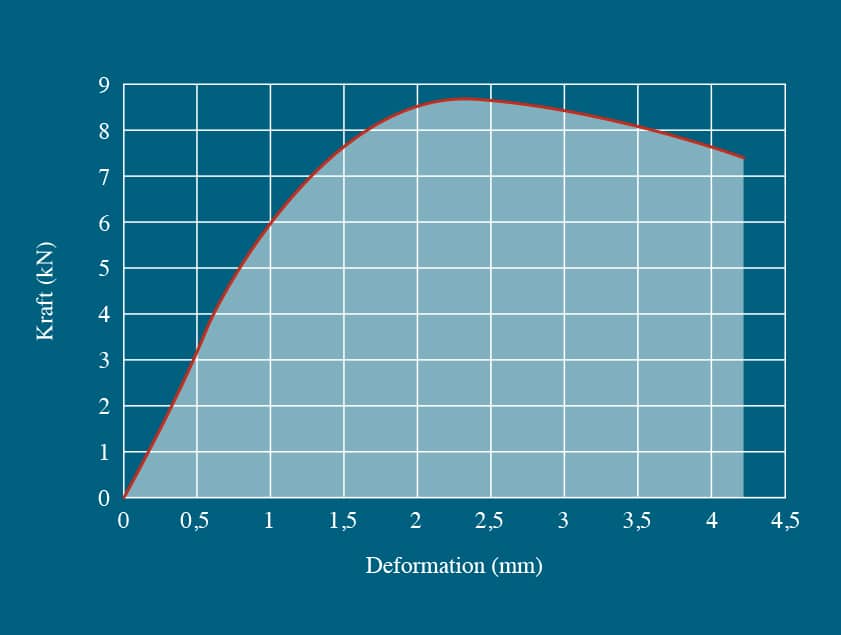

Bending test, profile with chipboard (without dampening element)

The bending test was performed by placing a steel rail with two support blocks mounted at a distance of 600 mm in a hydraulic press, after which a point load was applied to the steel rail between the support blocks. Force and deformation were recorded.

04

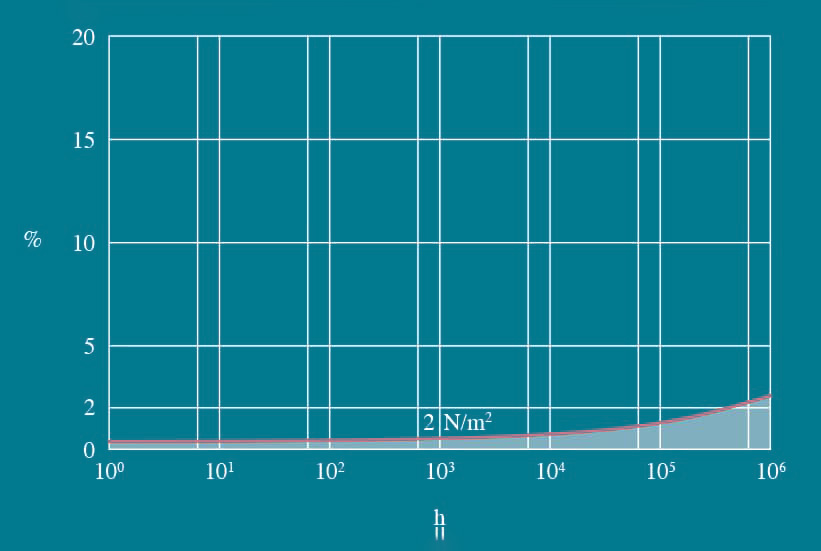

Fatigue test of installed Granab floor construction

The fatigue test was performed over a support block on the test floor by pulsing the load between 0.1 Fk and 0.6 Fk 10000 times at a rate of 1 Hz. Fk was the characteristic value from the load test of the support block. A total of two fatigue tests were performed over support blocks in the outer corners of the test floor. The load was pulsed between 0.1 and 0.6 Fk where Fk was set to 8.5 kN. Both load tests were performed without any permanent deformation or damage.

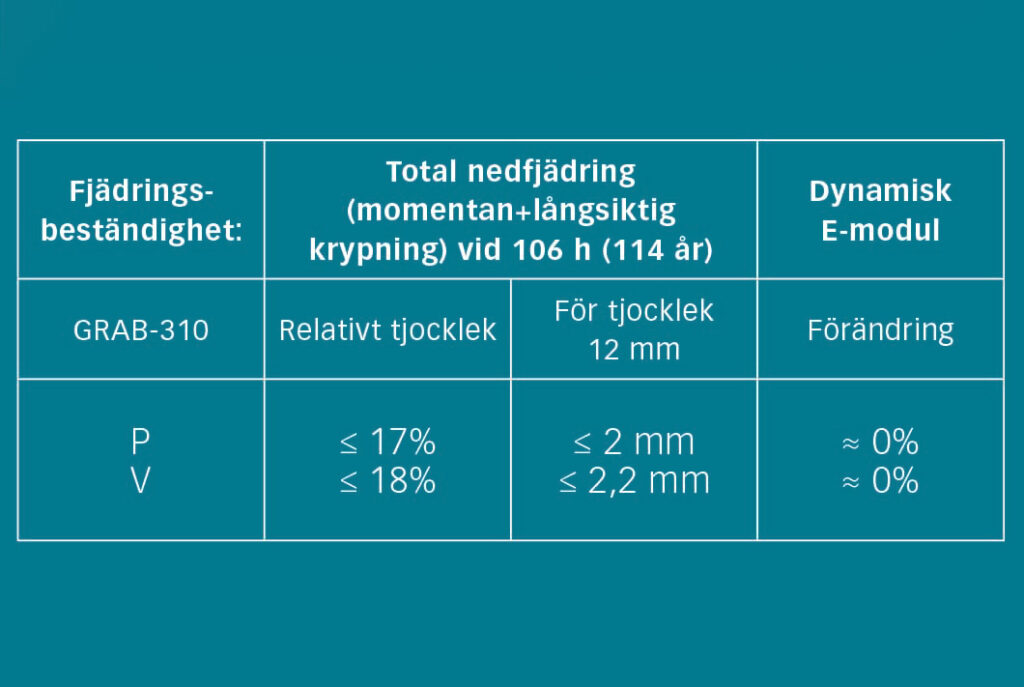

Dampening element

Support block with adjustment screw